What is a Wood I Beam?

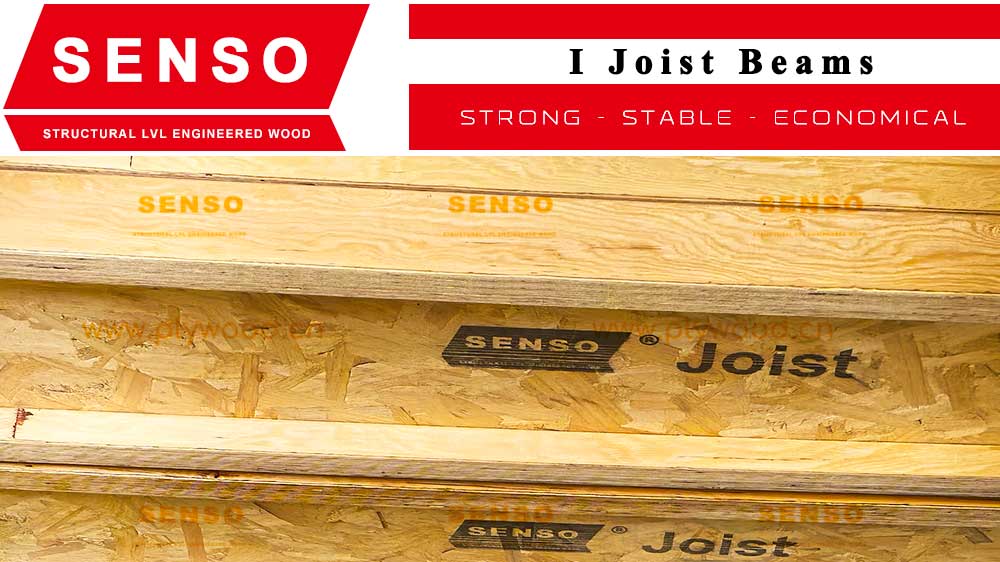

A wood I beam, also known as an engineered wood beam or I joist, is an advanced construction material that resembles the shape of the letter ‘I’. It is composed of a top and bottom flange made of laminated veneer lumber (LVL) or solid wood, with a web of oriented strand board (OSB) or plywood in between. The design of the wood I beam provides excellent strength-to-weight ratio, making it a popular choice for long-span applications in construction. These beams are used extensively in residential, commercial, and industrial building projects due to their strength, cost-effectiveness, and ease of installation. The lightweight design also allows for greater precision during installation, which is crucial for maintaining structural integrity.

Why Choose Wood I Beam for Construction?

Wood I beams are engineered to provide optimal strength while reducing weight. This unique combination makes them ideal for a wide range of structural applications, from flooring systems to roof frameworks.

The flanges of wood I beams are typically made from high-grade lumber or LVL beams, which provide exceptional stiffness and load-bearing capacity. The web, which connects the flanges, is made from OSB or plywood, giving the beam its characteristic ‘I’ shape. This combination of materials results in a beam that is not only strong but also lightweight and easy to handle.

Wood I Beam vs. Solid Timber Beams

One of the most common comparisons in construction is between wood I beams and traditional solid timber beams. While both materials have their merits, wood I beams offer several key advantages over solid timber.

Strength and Stability

Wood I beams are designed to maximize strength and minimize weight. The engineered design ensures that the beams are less prone to warping, twisting, or shrinking, which are common issues with solid timber beams. This stability is crucial in maintaining the structural integrity of a building, especially in areas that are prone to changes in humidity and temperature.

Cost Efficiency

Solid timber beams can be expensive, especially when high-quality, defect-free wood is required. Wood I beams, on the other hand, are made from engineered materials, which means they can be produced more efficiently and with less waste. This translates to cost savings for builders and homeowners alike.

Applications of Wood I Beams in Construction

Wood I beams are incredibly versatile and can be used in a variety of structural applications. Their lightweight nature makes them easy to install, while their engineered strength ensures they can handle significant loads.

Flooring Systems

One of the primary uses of wood I beams is in flooring systems. The beams are strong enough to support heavy loads while spanning long distances, which reduces the need for intermediate supports. This allows for more open floor plans and greater design flexibility.

Roof Framing

Wood I beams are also commonly used in roof framing. Their ability to span long distances without sagging makes them ideal for supporting roof loads. Additionally, the lightweight nature of wood I beams makes them easier to lift and position, which can speed up construction times.

Wood I Beam vs. Laminated Beams

Another important comparison is between wood I beams and laminated beams, such as glulam beams. Both are popular choices in modern construction, but they serve different purposes and offer distinct advantages.

Load-Bearing Capacity

Laminated beams, or glulam beams, are made by gluing together layers of wood to create a solid, load-bearing member. While glulam beams are incredibly strong and can handle very high loads, they are also heavy and more challenging to work with. Wood I beams, on the other hand, offer a balance of strength and weight, making them easier to install without heavy machinery.

Flexibility in Design

Wood I beams are available in a wide range of sizes and lengths, allowing builders to choose the perfect beam for their project. Laminated beams are also customizable, but their heavier weight can limit their use in certain applications where ease of installation is a priority.

Benefits of Using Wood I Beams

Wood I beams offer several benefits that make them a popular choice in the construction industry.

Lightweight Design

One of the most significant advantages of wood I beams is their lightweight design. Compared to solid timber or laminated beams, wood I beams are easier to transport and install. This can lead to significant time and cost savings on a construction project.

Reduced Environmental Impact

Wood I beams are also considered to be more environmentally friendly compared to solid wood beams. They are made from smaller trees and engineered wood products, which means less waste is generated during production. Additionally, the efficient use of wood resources helps to minimize the environmental impact of construction projects.

Wood I Beam vs. LVL Beams

LVL (Laminated Veneer Lumber) beams are another popular choice in construction, and they are often compared to wood I beams. Both materials are engineered for strength and stability, but there are some differences worth noting.

Structural Performance

LVL beams are known for their high strength and uniformity, which makes them suitable for heavy load-bearing applications. However, they are heavier than wood I beams, which can make installation more challenging. Wood I beams, with their lightweight design, are often preferred in situations where ease of handling is a priority.

Cost Considerations

LVL beams can be more expensive than wood I beams, particularly for long-span applications. Wood I beams provide a cost-effective alternative without compromising on performance, making them an attractive option for budget-conscious builders.

FAQs About Wood I Beams

Q: What are wood I beams used for?

A: Wood I beams are used for flooring systems, roof framing, and other structural applications in residential and commercial buildings.

Q: How do wood I beams compare to solid wood beams?

A: Wood I beams are lighter, more stable, and less prone to warping compared to solid wood beams.

Q: Are wood I beams environmentally friendly?

A: Yes, wood I beams are made from engineered wood products, which use smaller trees and generate less waste compared to solid wood beams.

Q: Can wood I beams be used in roof construction?

A: Yes, wood I beams are commonly used in roof framing due to their strength and ability to span long distances without sagging.

Q: What is the difference between wood I beams and LVL beams?

A: Wood I beams are lighter and easier to handle, while LVL beams are heavier but provide higher load-bearing capacity.

Post time: Feb-18-2025