The Dawn of a New Era in Construction: Walk Plank Takes Center Stage

In an industry where safety and efficiency are paramount, the introduction of the walk plank, also known as scaffold boards or scaffolding planks. It marks a significant milestone. These innovative planks are not just another addition to the construction toolkit. They are a revolutionary step forward, offering unparalleled benefits in safety, durability, and efficiency.

What kind of wood is OSHA plank?

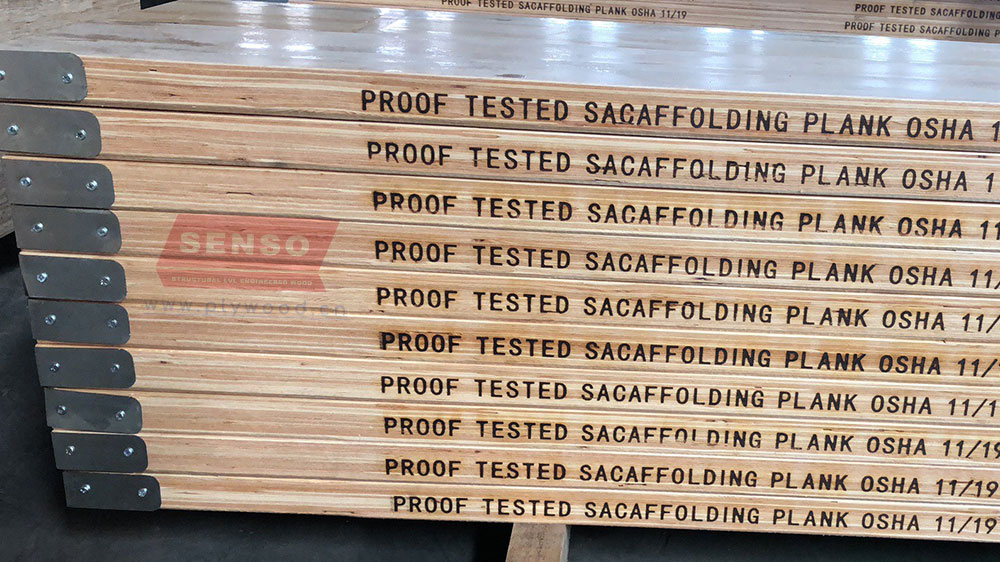

OSHA scaffold plank refers to scaffold planking that meets the safety standards set by the Occupational Safety and Health Administration (OSHA) in the United States. These planks can be made from various types of wood. But they must adhere to specific guidelines regarding strength, dimensions, and load-bearing capacity to ensure safety in construction and industrial environments.

Commonly, OSHA scaffold planks are made from:

Pine : This is a popular choice due to its strength, durability, and availability. Southern Yellow Pine has a high load-bearing capacity, making it suitable for heavy-duty use.

Fir: Another common material, Douglas Fir is known for its strength and stiffness, making it an excellent choice for scaffolding planks.

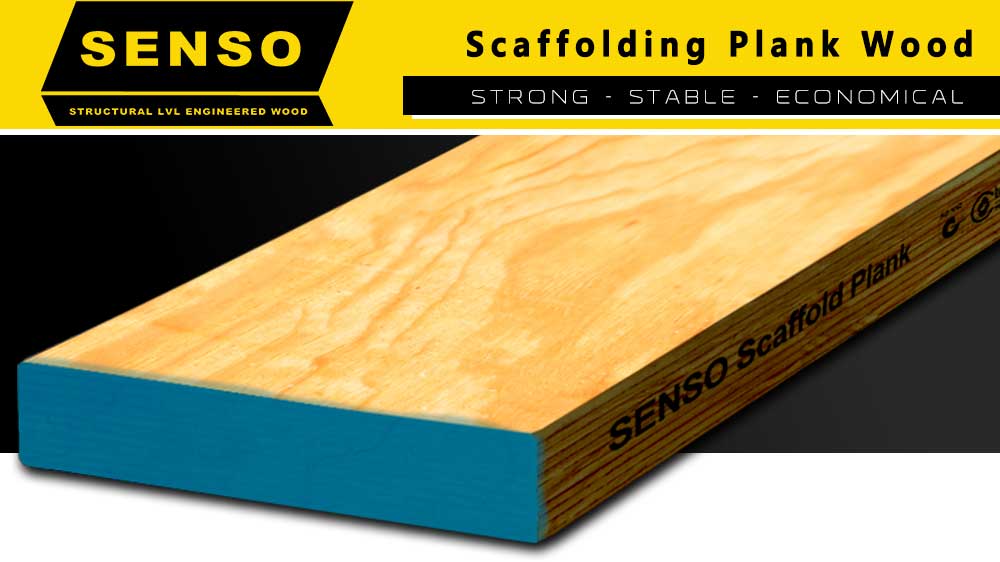

Engineered Wood: Some OSHA scaffolding planks are made from engineered wood products like Laminated Veneer Lumber (LVL). These are manufactured to meet or exceed the strength requirements set by OSHA and can be more uniform in quality compared to natural lumber.

Safety First: How Walk Plank is Redefining Standards

At the heart of the walk plank’s design is an unwavering commitment to safety. Traditional scaffolding solutions have long been plagued by issues such as instability and susceptibility to environmental factors. Walk plank addresses these concerns head-on with its robust construction and advanced materials. The unique design incorporates features that significantly reduce the risk of slips and falls, a common hazard on construction sites.

Durability That Lasts: The Walk Plank Advantage

Beyond safety, durability is a key factor in the growing popularity of walk planks. Made from high-quality materials, these planks withstand the test of time and harsh environmental conditions. This longevity not only ensures continuous safety but also offers economic benefits by reducing the need for frequent replacements.

Efficiency in Construction: A Game-Changer for Projects

The introduction of walk plank in construction projects is not just about safety and durability; it’s also about efficiency. Their ease of installation and versatility in various construction scenarios streamline project timelines. This efficiency is a boon for construction companies looking to complete projects faster without compromising on quality or safety.

The Environmental Edge: Walk Plank’s Sustainable Approach

In an era where environmental consciousness is growing, walk plank stands out with its sustainable approach. The materials used in their construction are often sourced from sustainable practices. And contributing to a reduced carbon footprint in the construction industry. This aspect of scaffold boards is particularly appealing to companies aiming to bolster their environmental credentials.

Testimonials and Case Studies: Walk Plank in Action

The effectiveness of walk plank is not just theoretical. Numerous construction projects have already benefited from their implementation. Testimonials from industry professionals underscore the practical advantages of these innovative planks in real-world scenarios.

Transforming Worksite Dynamics: Walk Plank in Large-Scale Construction

The impact of scaffolding plank is most prominently seen in large-scale construction projects. These environments, characterized by their complexity and the high volume of activity. It require solutions that can withstand intense usage while ensuring worker safety. Walk plank has proven to be exceptionally well-suited for such demands. Its robustness and reliability make it a preferred choice for projects ranging from high-rise buildings to extensive infrastructure developments.

Innovations in Design: The Technical Edge of Walk Plank

What sets walk plank apart in the highly competitive construction industry is its innovative design. These planks are engineered with precision, incorporating advanced materials and construction techniques. The integration of non-slip surfaces, enhanced load-bearing capacities, and resistance to warping and weathering are just a few of the technical advancements that define walk plank. This commitment to innovation ensures that walk plank remains at the cutting edge of construction technology.

Enhanced Productivity: Walk Plank’s Contribution to Project Timelines

One of the less discussed but equally significant benefits of walk plank is its contribution to enhanced productivity. Construction projects are often under tight deadlines, and any solution that can expedite processes without compromising safety is highly valuable. scaffolding board does exactly this. Its ease of installation and handling allows for quicker setup and dismantling, saving valuable time. This time efficiency translates into cost savings and more competitive project bids.

A Focus on Training and Best Practices

While scaffold boards offers numerous advantages, its full potential is realized when used in conjunction with proper training and best practices. Recognizing this, manufacturers and industry bodies have collaborated to provide comprehensive training programs. These programs ensure that workers are proficient in the safe and effective use of walk planks, maximizing the benefits while minimizing risks.

The Global Reach of Walk Plank: International Adoption and Standards

The adoption of walk plank is not limited to a particular region or country; it’s a global phenomenon. Different countries, each with their unique construction challenges, have found value in incorporating scaffolding plank into their projects. This international adoption has also led to the establishment of global standards, ensuring that walk planks meet rigorous safety and quality criteria regardless of where they are used.

Adapting to Diverse Construction Scenarios

The versatility of scaffolding board is another factor contributing to its widespread use. Whether it’s residential construction, commercial developments, or public infrastructure projects, walk plank has shown remarkable adaptability. Its design allows for use in a variety of settings, from the tight spaces of urban construction sites to the expansive areas of industrial projects.

The Economic Implications: Cost-Effectiveness of Walk Plank

Beyond safety and efficiency, walk plank also presents a compelling economic case. While the initial investment might be higher than traditional scaffolding solutions, the long-term savings are significant. Reduced maintenance costs, lower replacement frequency, and increased productivity all contribute to a favorable return on investment.

Integrating Technology with Walk Plank: The Next Frontier

As the construction industry moves forward, integrating technology with tools like scaffold boards is becoming increasingly important. Innovations such as smart sensors and IoT (Internet of Things) integration are on the horizon. These technologies can monitor the condition and usage of walk planks in real-time, providing valuable data that can further enhance safety and efficiency. This integration represents the next step in the evolution of construction technologies, where physical tools and digital insights converge for optimal results.

Championing Environmental Sustainability

In an age where environmental sustainability is crucial, scaffolding plank is contributing positively by incorporating eco-friendly materials and manufacturing processes. The use of recyclable materials, coupled with longer lifespans, means a significant reduction in waste. This aspect of scaffolding board aligns with the growing trend of green construction practices, making it a choice that benefits not only the present but also the future.

Addressing the Skills Gap: Walk Plank as a Training Tool

The construction industry is facing a skills gap, with a growing need for trained professionals. Walk plank plays a role in addressing this issue by being an excellent training tool. Its intuitive design and safety features make it ideal for training new workers, helping them acclimatize to construction environments safely and efficiently. This aspect positions scaffold boards as more than just a piece of equipment; it’s a facilitator of industry growth and professional development.

Case Studies: Walk Plank in Diverse Environments

The versatility and effectiveness of walk plank are best illustrated through diverse case studies. From the bustling streets of major cities where they are used in high-rise construction, to remote areas where they facilitate infrastructure development, walk planks have proved their worth. These case studies not only highlight the practicality of walk planks but also demonstrate their adaptability to various environmental and logistical challenges.

The Future Outlook: Innovation and Expansion

The future of scaffolding plank looks bright, with continuous innovation being a key driver. As new materials and technologies emerge, scaffolding board will likely incorporate these advancements, further enhancing its capabilities. Additionally, the expanding global construction market presents more opportunities for the application of scaffold boards in various projects, solidifying its position as a staple in modern construction.

Building a Safer Tomorrow: The Enduring Legacy of Walk Plank

Ultimately, the legacy of walk plank in the construction industry will be defined by its contribution to building a safer, more efficient, and sustainable future. By consistently pushing the boundaries of what is possible in construction safety and efficiency, scaffold boards is not just a tool for today but a foundation for tomorrow.

Embracing Change, Ensuring Safety: The Walk Plank Story

As we conclude our in-depth exploration of walk plank. It’s clear that its impact on the construction industry is profound and far-reaching. From enhancing worker safety and project efficiency to driving environmental sustainability and innovation, walk plank represents a significant leap forward in construction technology. Its role in shaping the future of the industry cannot be overstated – scaffolding board is more than just a piece of equipment; And scaffolding plank is a symbol of progress, a beacon of safety. A testament to the industry’s commitment to continuous improvement. The scaffolding plank story is not just about a product; it’s about a movement towards a safer, more efficient, and sustainable construction industry.

Post time: Dec-13-2023