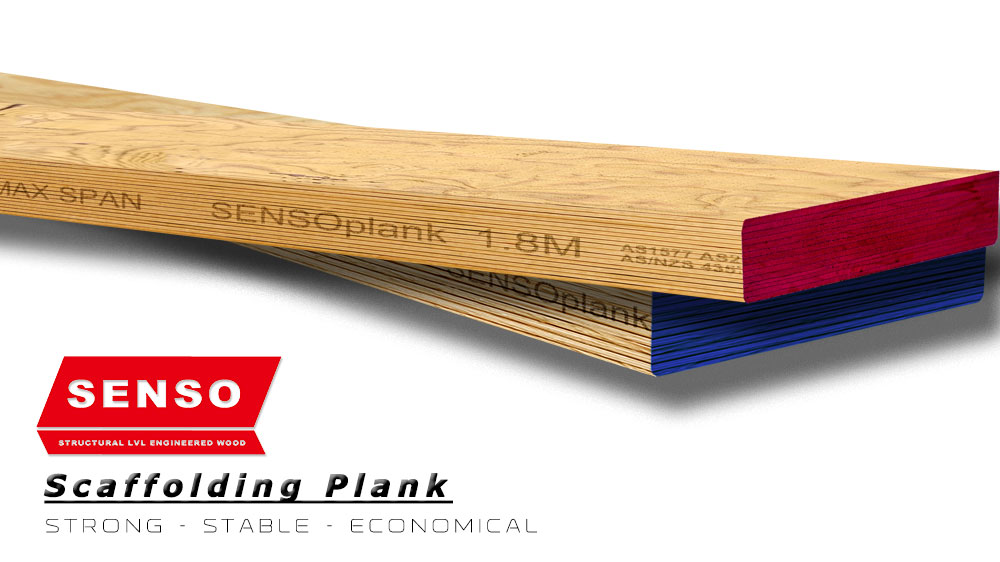

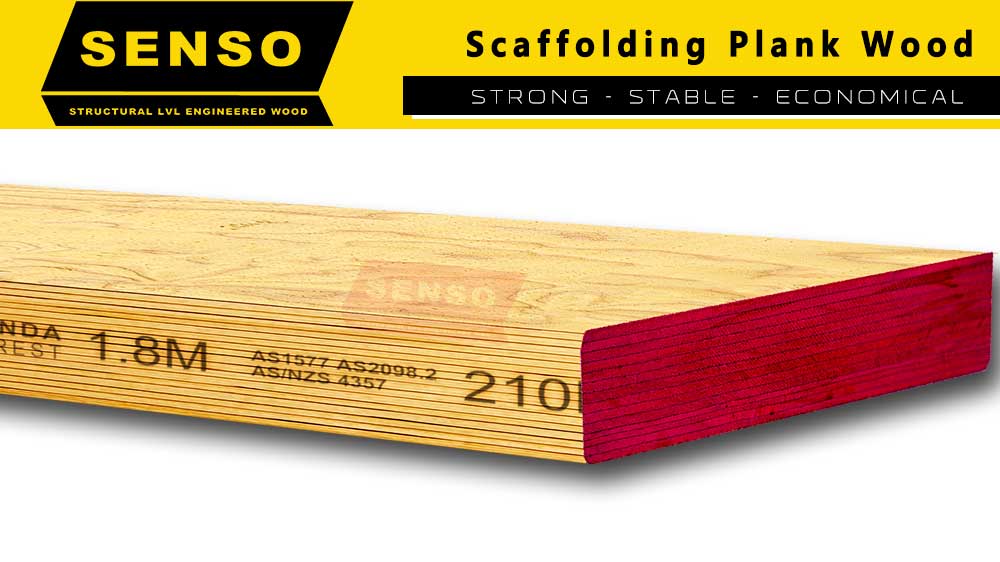

What is a Scaffolding Board?

A scaffolding board is also known as a scaffold board, scaffold plank, or walk plank. It is essential in construction and building maintenance. These boards are horizontal platforms in scaffolding systems. They offer a stable, secure workspace for workers at different heights. Traditionally wooden, modern boards have evolved significantly. They now include innovative materials and designs. This evolution addresses the growing needs for safety, durability, and efficiency in construction.

Evolving Designs for Enhanced Safety and Efficiency

The evolution of scaffolding boards has been significant in recent years. The introduction of new materials such as aluminum and reinforced composites has led to lighter, more durable, and more resilient designs. These advancements not only reduce the overall weight of scaffolding structures but also offer increased strength and longevity. Moreover, modern scaffold boards often come with integrated safety features such as non-slip surfaces and enhanced load-bearing capacities, ensuring greater safety for workers.

Lightweight and Durable Materials

Innovative materials are at the forefront of modern scaffolding board design. Aluminum, known for its strength-to-weight ratio, has become a popular choice. It offers the durability required for heavy-duty construction work while significantly reducing the weight of scaffolding structures. This not only makes transport and setup more manageable but also minimizes the stress on supporting structures, an essential factor in renovation or restoration projects.

Integrated Safety Features

Today’s scaffold boards are designed with worker safety as a priority. Features such as non-slip surfaces are standard, providing a secure footing in various weather conditions. Additionally, some boards are designed with raised edges or toe boards, minimizing the risk of tools or materials accidentally being knocked off the scaffold, further enhancing onsite safety.

Environmental Considerations

Sustainability is increasingly important in construction materials, and scaffolding boards are no exception. Eco-friendly options, such as boards made from recycled materials or sustainably sourced wood, are becoming more prevalent. These choices not only support environmental stewardship but also align with the growing demand for green building practices.

Application in Modern Construction

Scaffolding boards play a vital role across numerous construction scenarios, from large-scale building projects to smaller residential renovations. Their versatility makes them ideal for a wide range of tasks, including masonry, painting, window installation, and more. The recent innovations in scaffolding board design have expanded their applicability, making them suitable for even the most challenging and unique construction environments.

Revolutionizing the Market: The Impact on Construction

The introduction of advanced scaffolding boards has significantly impacted the construction industry, leading to improved efficiency and safety standards. This section explores the market trends influenced by these innovations and the practical benefits they offer.

Enhancing Construction Efficiency

The lightweight nature of modern scaffold boards, particularly those made from materials like aluminum, has streamlined the construction process. Easier to transport and set up, these boards reduce the time and labor required for scaffolding assembly. This efficiency is particularly beneficial in urban areas where construction time is often limited due to various regulations and the need to minimize disruption.

Improving Safety Standards

Safety is paramount in construction, and the latest scaffold boards have set new benchmarks. Their robust design, featuring enhanced load-bearing capacities and non-slip surfaces, has reduced workplace accidents. The integration of safety features directly into the board’s design, such as toe boards, further ensures that the risks of falls and dropped tools are minimized, creating a safer work environment for everyone involved.

Versatility Across Construction Scenarios

Modern scaffolding boards are versatile, catering to a wide range of construction projects. From high-rise buildings to historical restorations, their adaptability allows for safe and efficient work in diverse settings. This versatility also extends to different weather conditions, with materials and designs that remain stable and secure even in adverse weather, a crucial factor in maintaining project timelines.

Scaffolding Boards in Specialized Applications

Apart from traditional construction, these boards find use in specialized applications. For instance, in restoration projects, the lightweight and non-invasive nature of modern scaffold boards ensure that the structural integrity of historical buildings is maintained. Similarly, in high-risk environments like offshore constructions, the durability and weather-resistant qualities of these boards are indispensable.

Advanced Scaffolding Board Technologies: A Game-Changer in Construction

The construction industry is witnessing a paradigm shift with the introduction of advanced scaffolding board technologies. These innovations are not just about materials and safety; they represent a holistic approach to efficiency, environmental responsibility, and adaptability to various construction scenarios.

Technological Integration in Scaffold Boards

Modern scaffold boards are more than just platforms; they incorporate advanced technologies that increase their functionality. For instance, some boards come equipped with embedded sensors to monitor stress, wear, and environmental conditions. This technology enables real-time monitoring of the scaffold’s structural integrity, ensuring safety and preventing potential hazards.

Customization and Adaptability

The adaptability of scaffolding boards to specific project needs is a significant advantage. Customization options, such as variable lengths and widths, allow these boards to be tailored to unique construction requirements. This adaptability is particularly valuable in projects with unusual or challenging designs, where standard scaffolding solutions might be insufficient.

Environmental Impact and Sustainability

The shift towards sustainable construction materials is evident in the production of scaffold boards. The use of recycled materials and sustainably sourced timber is becoming more common, aligning with global environmental goals. Furthermore, the longevity and recyclability of modern scaffold boards reduce waste and carbon footprint, making them a preferred choice in green construction projects.

The Role of Scaffolding Boards in Urban Development

Urban construction projects present unique challenges, from space constraints to noise and pollution regulations. Advanced scaffolding boards play a crucial role in addressing these challenges, offering solutions that are not only efficient but also considerate of urban environments.

Space Optimization and Noise Reduction

In densely populated urban areas, space is at a premium. Lightweight and easily maneuverable scaffold boards facilitate efficient use of limited space. Additionally, the reduced noise associated with the handling and installation of these modern boards is a significant advantage in noise-sensitive urban areas.

Safety in High-Traffic Areas

Construction in urban areas often occurs alongside busy streets and pedestrian zones. The enhanced safety features of modern scaffold boards, such as improved load-bearing capacities and anti-slip surfaces, are essential in these environments. They ensure worker safety while also minimizing the risk to the public.

Aesthetic Considerations

In urban settings, the visual impact of construction work cannot be ignored. Modern scaffolding boards offer a more streamlined and less obtrusive appearance. Some boards are even designed with aesthetics in mind, blending in with the urban landscape and reducing the visual disruption typically associated with construction sites.

Innovations in Manufacturing and Supply Chain

The manufacturing processes of scaffolding boards have evolved, embracing technologies that enhance efficiency and quality. Automation and precision engineering ensure consistent quality, while advanced logistics solutions facilitate timely and efficient distribution, crucial in fast-paced construction environments.

Enhanced Manufacturing Techniques

The use of automated manufacturing processes ensures high precision and uniformity in scaffold boards. This consistency is vital for safety and performance. Advanced materials science is also employed in the development of boards that are both lighter and stronger, meeting the rigorous demands of modern construction.

Streamlined Supply Chain

The supply chain for scaffolding boards has become more efficient, with advancements in logistics and inventory management. This efficiency ensures that construction projects can receive the materials they need without delays, which is crucial in maintaining project timelines and budgets.

Navigating Challenges and Maximizing Opportunities with Scaffold Boards

As the construction industry continues to evolve, scaffolding boards play a pivotal role in navigating the challenges and seizing the opportunities that arise. This section delves into the future prospects, regulatory considerations, and the broader impact of these innovations on the construction sector.

Future Prospects in Scaffold Board Technology

The future of scaffolding board technology is poised for even greater advancements. Emerging trends include the integration of smart technologies for enhanced safety monitoring, further material innovations for increased sustainability, and designs that cater to increasingly complex architectural structures. The potential for these boards to become even more integrated with digital construction processes, such as Building Information Modeling (BIM), opens new avenues for efficiency and precision in construction projects.

Regulatory Landscape and Compliance

As technologies advance, so do the regulations governing their use. Compliance with local and international safety standards is paramount in the manufacturing and utilization of scaffolding boards. Future developments will need to align with evolving regulatory frameworks, ensuring that these innovations continue to enhance safety and efficiency without compromising regulatory compliance.

Training and Skill Development

With the introduction of advanced scaffolding boards, there is an increasing need for skilled professionals who can effectively utilize these technologies. Training programs and certifications are becoming more crucial, ensuring that construction workers and supervisors are equipped with the knowledge and skills to safely and efficiently work with modern scaffold systems. This focus on training not only enhances safety on construction sites but also contributes to the professional development of workers in the industry.

Broader Impact on the Construction Industry

The advancements in scaffolding board technology have a far-reaching impact on the construction industry. They are catalysts for change, driving the industry towards more sustainable, efficient, and safer construction practices.

Driving Sustainable Construction Practices

The use of eco-friendly materials and the emphasis on recyclability and sustainability in scaffold board manufacturing resonate with the global shift towards green building practices. This shift not only contributes to environmental conservation but also aligns with the growing consumer and regulatory demand for sustainable construction methods.

Enhancing Global Construction Standards

The innovation in scaffold boards sets new benchmarks in construction standards globally. As these technologies become more widespread, they raise the bar for safety, efficiency, and sustainability in construction projects around the world, fostering a culture of continuous improvement and innovation in the sector.

Economic Implications

The development and adoption of advanced scaffold boards also have significant economic implications. They contribute to cost savings in the long run through increased efficiency, reduced material waste, and lower accident rates. Additionally, the growth in this sector creates new business opportunities and jobs, contributing to the broader economy.

Scaffold Board Frequently Asked Questions (FAQs)

What is a scaffold board?

A scaffold board, also known as a scaffolding plank or walk plank, is a horizontal platform used in scaffolding systems. It provides a stable and secure workspace for construction workers at various heights. These boards are integral to construction and maintenance work, offering a reliable surface for workers and materials.

What size boards are used for scaffolding?

The size of scaffolding boards varies depending on the project requirements and the type of scaffolding system used. Common lengths range from 4 feet to 16 feet, with a width of about 9 inches. The thickness can vary, but a standard size is usually around 1.5 inches. It’s crucial to select the appropriate size for specific construction needs to ensure safety and efficiency.

How many types of scaffolding boards are there?

There are several types of scaffolding boards, including timber boards, metal boards (often aluminum), and composite boards. Each type has its unique advantages, such as the traditional feel and cost-effectiveness of timber or the durability and lightness of metal and composite materials.

Why use toe boards on scaffolding?

Toe boards are used on scaffolding to prevent tools, materials, or debris from falling off the edges, which could pose a serious safety risk to workers and pedestrians below. They are part of the essential safety measures in scaffold design, contributing to a safer construction environment.

How strong are scaffold boards?

The strength of scaffold boards depends on the material and construction. Timber boards must adhere to specific grades and quality standards, while metal and composite boards are designed for high strength and load-bearing capacity. Modern scaffold boards are tested rigorously to meet safety standards, ensuring they can support the weight of workers and their equipment securely.

Scaffolding Board Solutions for Modern Building

Scaffolding boards are a critical component in the construction and maintenance industries, evolving continually to meet the demands of modern building projects. With advancements in materials and design, these boards not only offer enhanced safety and efficiency but also reflect an ongoing commitment to sustainability and worker welfare. As the industry progresses, the role of innovative scaffolding solutions like these will be pivotal in shaping the future of safe and efficient construction practices.

Post time: Jan-10-2024