Laminated Wood is revolutionizing the construction industry

What Is Laminated Wood?

Laminated wood, commonly known by its synonyms like LVL Beams or Wooden Beams, is a composite wood product manufactured by bonding layers of wood together. It has gained prominence for its exceptional strength, durability, and environmental benefits.

The Significance of Laminated Wood

The construction industry is undergoing a significant shift towards sustainable practices, and LVL beam is at the forefront of this movement. The material serves as a greener alternative to steel and concrete, without sacrificing performance.

The Anatomy of Laminated Wood

How Is It Made?

Laminated wood is manufactured by layering thin sheets of wood and binding them together with durable adhesives. This layered structure significantly enhances its strength and stability.

Types of Laminated Wood

Different types of structural LVL, including LVL Timber, are tailored for specific applications. The wood types and adhesives used can be altered to fit the intended use, whether it’s for residential or commercial construction.

Comparing Laminated Wood and Traditional Timber

Strength and Durability

Laminated wood outperforms traditional timber in terms of both strength and durability. Its engineered structure allows for better load distribution, making it ideal for structures that require high-stress resistance.

Environmental Impact

Traditional timber requires the felling of whole trees, whereas LVL timber can be manufactured from smaller pieces and offcuts. This feature significantly reduces waste and promotes sustainable forest management.

Applications of Laminated Wood

Residential Construction

Laminated wood has seen wide adoption in residential construction for elements like load-bearing walls and roof trusses. It offers a durable and eco-friendly solution that is also aesthetically pleasing.

Commercial and Public Buildings

In larger commercial and public buildings, LVL beam provides an ideal solution for creating expansive, open spaces without the need for numerous supporting columns.

Advantages of Laminated Wood

Cost-Effectiveness

While the initial cost of LVL timber may be higher than traditional lumber, it often proves to be a more cost-effective option in the long run. Its superior strength and durability mean less frequent repairs and lower maintenance costs.

Sustainability

Laminated wood has an excellent environmental profile. It acts as a carbon sink, absorbing CO2 from the atmosphere. In comparison, the production of concrete and steel releases significant amounts of CO2.

Design Flexibility

The engineered nature of structural LVL allows for more design freedom. Unlike traditional timber, it can be molded into various shapes and sizes, accommodating innovative architectural designs.

Regulatory Landscape

Building Codes

Over the years, building codes have started to acknowledge the performance and sustainability benefits of laminated wood. While local regulations may vary, the material is increasingly being accepted as a go-to option for construction.

Certifications

Various international bodies certify LVL beam for its eco-friendliness and performance. Obtaining these certifications can enhance the marketability of structures built with laminated wood.

Market Trends and Consumer Preferences

Growing Popularity

The increasing adoption of sustainable construction practices has made LVL beam more popular. More architects, builders, and homeowners are recognizing its advantages, contributing to its growing market share.

Technological Advancements

Innovations in manufacturing technology have led to even more robust and versatile laminated wood products. These advancements have expanded its applications, from large commercial complexes to small DIY projects.

Handling and Maintenance

Installation

The installation of LVL timber generally follows the same principles as traditional timber but offers the added benefit of lighter weight, making the construction process quicker and less labor-intensive.

Maintenance Tips

Laminated wood requires minimal maintenance. Simple practices like regular cleaning and periodic inspections for damage can go a long way in prolonging its lifespan.

Popular Applications of Laminated Wood

Residential Housing

Due to its strength and flexibility, structural LVL has become an excellent material for residential construction. It’s especially popular for creating open-concept spaces, a trend that shows no signs of slowing down.

Commercial Buildings

The commercial sector is also embracing the benefits of laminated wood. From office buildings to retail spaces, the material provides an eco-friendly and aesthetically pleasing alternative to traditional construction materials.

Infrastructure

LVL timber isn’t just for buildings; it’s also finding applications in public infrastructure. From bridges to utility poles, the material’s strength and durability make it a top choice for these demanding applications.

Laminated Wood vs. Other Materials

Laminated Wood vs. Steel

Steel has been a traditional favorite for many types of construction. However, LVL beam offers a lighter weight and more sustainable alternative, without sacrificing much in terms of strength and durability.

Laminated Wood vs. Concrete

While concrete has excellent compressive strength, laminated wood outperforms it in tensile strength, making it a better choice for certain applications. It also offers superior thermal insulation.

The Future of Laminated Wood

Research and Development

Continuous research is opening new possibilities for LVL timber. Current studies are exploring its use in high-rise buildings and even in earthquake-prone areas, thanks to its natural flexibility.

Consumer Awareness

As awareness about climate change grows, more consumers are leaning towards sustainable products. This shift is likely to benefit the structural LVL industry, as people increasingly opt for greener construction materials.

How to Choose High-Quality Laminated Wood

Vendor Selection

When looking for structural LVL, ensure the vendor complies with international standards for quality and sustainability. Customer reviews and expert opinions can help in making an informed decision.

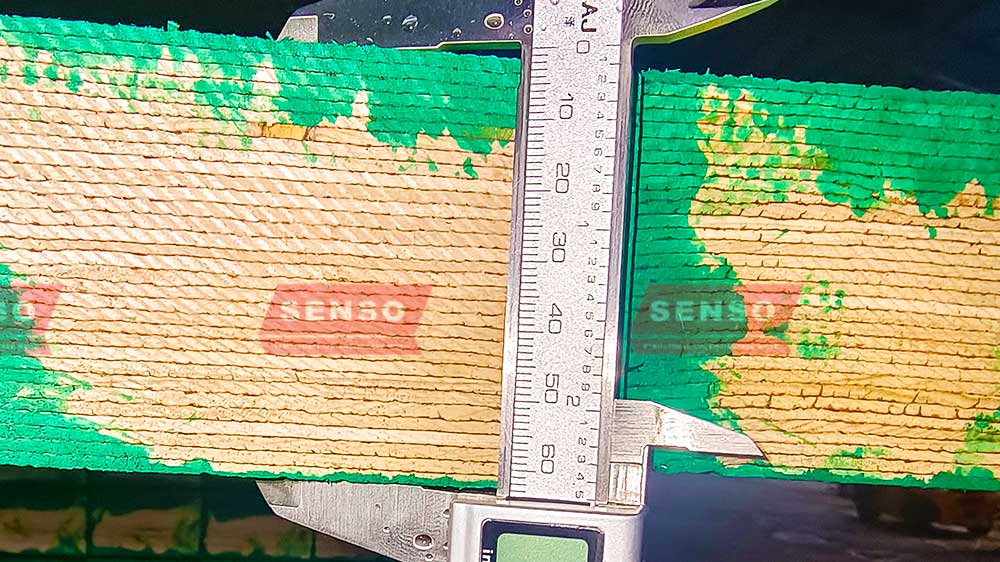

Material Inspection

Before purchasing, inspect the laminated wood for uniformity, finish quality, and absence of defects. It can save you from potential issues during construction.

Maintaining Laminated Wood Structures

Periodic Inspections

Regular inspections of LVL beam structures can go a long way in preserving their beauty and integrity. Look for signs of wear and tear or insect activity, and address issues promptly.

Cleaning and Treatment

Proper cleaning methods can also extend the life of laminated wood. Use mild detergents and avoid abrasive cleaners that can damage the wood’s surface. Periodic treatments with sealants can further enhance durability.

Repairs and Refurbishments

Damaged LVL timber can often be repaired without requiring a full replacement. This property makes it both cost-effective and less wasteful in terms of resources.

The SENSO Brand’s Commitment to Quality

SENSO has a longstanding commitment to delivering high-quality LVL timber products. Our state-of-the-art manufacturing facilities follow rigorous quality standards to ensure you get the best material for your projects.

Quality Control

Every batch of structural LVL from SENSO undergoes rigorous quality control checks. From sourcing the best raw materials to overseeing the manufacturing process, quality is our top priority.

Environmental Responsibility

In addition to quality, SENSO takes its environmental responsibilities seriously. Our LVL beam is sourced from sustainably managed forests, contributing to responsible construction practices.

Laminated Wood – Advancing Sustainable Building Practices

Laminated wood has come a long way, from its initial use in aircraft during World War II to its contemporary applications in modern architecture and construction. It’s a material that combines aesthetic appeal with functional advantages, making it a prime choice for a range of uses.

Sustainability, adaptability, and reliability are just some of the numerous benefits of LVL timber. These factors make it an excellent choice for construction, be it residential, commercial, or public infrastructure.

In a world increasingly aware of the need for sustainable choices, structural LVL stands out as a material that doesn’t compromise on quality or aesthetic appeal. Whether you’re planning a small home renovation or a large-scale commercial project, this versatile material has something to offer.

When it comes to high-quality laminated wood, SENSO remains a trusted name in the industry, dedicated to sustainability, innovation, and quality.

Post time: Sep-23-2023