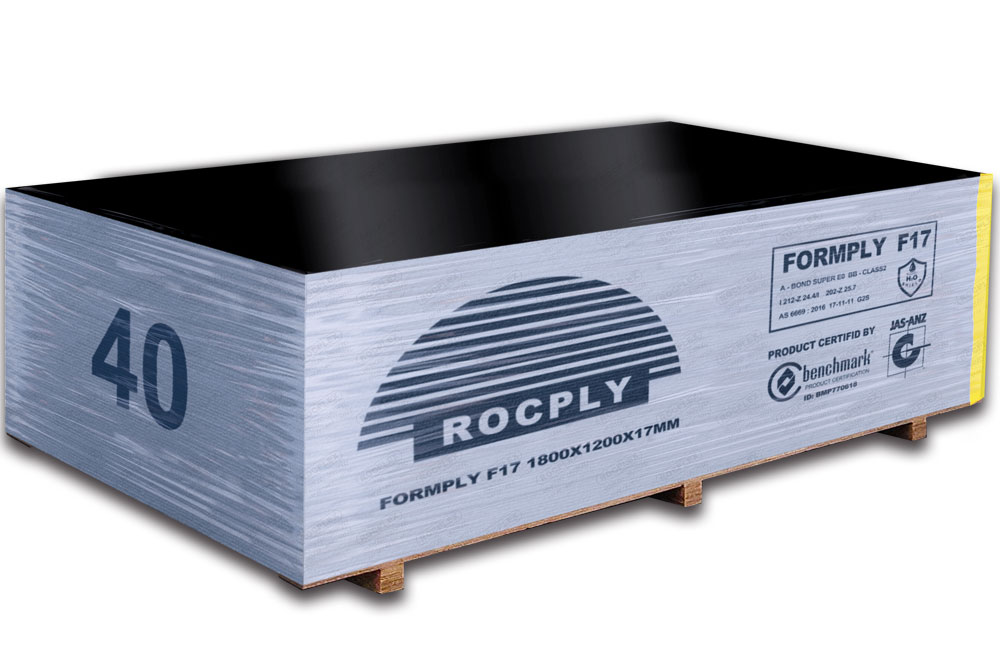

Formply F17 AS 6669 Certified

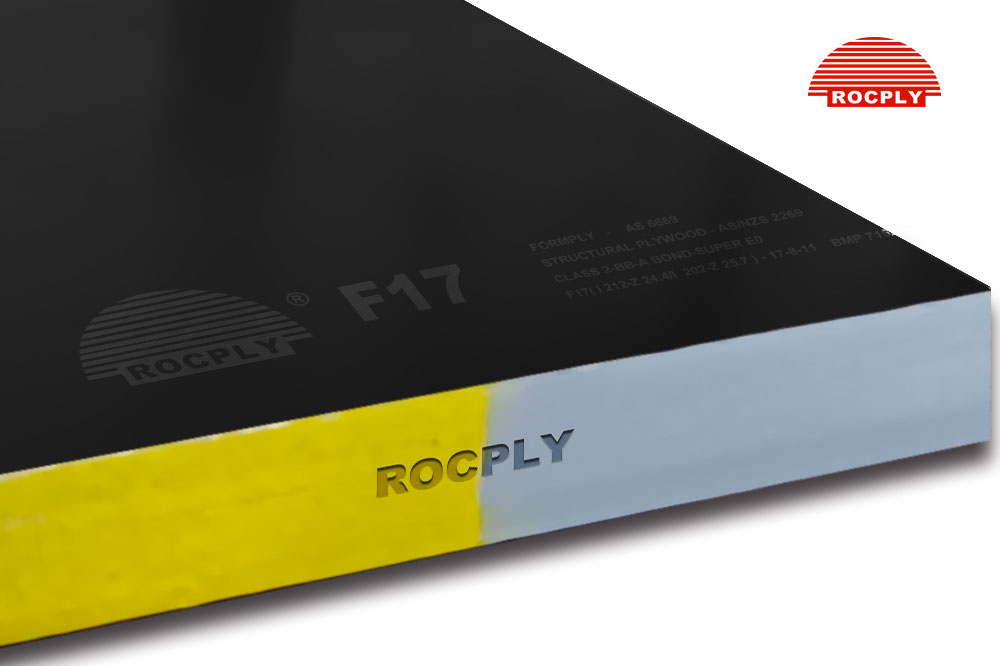

ROCPLY ® F17 grey edge yellow stripe formply is constructed from mixed species veneers with a hardwood face and phenolic overlay.

Its high durability positions it as an ideal material for diverse formwork applications, from decks to precast and tilt-up panel construction. Notably, ROCPLY F17 Formply has the unique distinction of dual-certification – holding both the AS 6669 and AS/NZS 2269 standard certifications by BENCHMARK and CERTMARK. .

ROCPLY ® F17 formply strength, durability, and availability in various sizes and thicknesses have made it a top choice among contractors and builders globally for projects ranging from foundations and walls to bridges. Manufactured from superior full hardwood veneers bonded together with a specially designed super E0 waterproof adhesive, ROCPLY F17 offers exceptional bonding strength, yielding a strong and stable plywood product.

ROCPLY Formply manufacturing process leverages oblique joint and hot-melt splicing technology to avoid potential gaps between veneers, ensuring solid and reliable plywood, particularly suitable for concrete formwork applications. Tailored specifically for the Australian market, ROCPLY F17 undergoes a rigorous three-tier quality control program that includes adhering to detailed manufacturing specifications, conducting in-house testing, and securing independent grading, testing, and certification by Certemark International (CMI) and the British Standards Institution (BSI).

By using certified Forest Stewardship Council (FSC) veneer from sustainable forests, ROCPLY manufacturing reflects the company’s commitment to responsible forestry practices. Thus, ROCPLY F17 Formply not only provides quality assurance and consistency but also remains a reliable, cost-effective choice for concrete formwork applications. Its superior construction, high-grade materials, and strict quality control processes make it an excellent choice for a variety of construction projects.

ROCPLY F17 Formply For Strong, Stable, Concrete Formwork

Surfaces Surfaces |

|

| The special HDO (High-Density Overlay) film facing used in ROCPLY F17 Form Ply provides a super smooth surface designed to resist water absorption and maintain its dimensional stability, which helps prevent the adhesion of concrete during the pouring and setting process. This makes it a durable and reliable choice for concrete formwork applications, even when exposed to moisture or humidity. |

Structure Structure |

|

| ROCPLY F17 made from high-grade full-hardwood veneers, miter joint design, and hot-melt splicing technology making ROCPLY F17 Form Ply a top product is known for its strength and durability, able to withstand the weight and pressure of heavy objects and is less prone to bending, warping or breaking. This helps ensure that the concrete form retains its integrity even after multiple uses. |

Bonding Bonding |

|

| ROCPLY F17 FormPly is made with A-bond Super E0 waterproof adhesive, which is a high-quality adhesive that provides superior bonding strength and water resistance. ROCPLY Laboratory boiling water test data far exceeds 90 hours, it still maintains its glue-sticking properties and will not become deformed. This is a testament to the adhesive used in the ROCPLY manufacturing process, which is able to withstand extreme conditions and remain strong and stable. |

Sealing Sealing |

|

| ROCPLY F17 FormPly is designed with 4 Times sealed edges that are painted with waterproof paint in the factory to minimize moisture penetration. The sealing design helps to prevent moisture and water from penetrating the plywood, which can help to prolong its lifespan and maintain its structural integrity. |

ROCPLY Formply Advantage

Features:

- ROCPLY Formply F17 is made from high-quality hardwood veneers that are bonded with waterproof glue, providing durability and resistance to wear and tear.

- The formwork plywood has a thickness of 17mm, making it sturdy and able to support heavy loads.

- ROCPLY Formply F17 is AS 6669 certified, ensuring that it meets Australian standards for formwork plywood.

- The plywood is treated with special chemicals that make it resistant to moisture, rot, and termites, ensuring a long lifespan.

- ROCPLY Formply F17 has a smooth surface that allows for easy release of formwork, reducing the need for extra release agents and saving time and money.

- The formwork plywood has a high strength-to-weight ratio, making it easy to handle and transport.

Benefits:

- ROCPLY Formply F17 is an ideal choice for construction projects that require sturdy, reliable formwork.

- The Formply is high-quality construction ensures that it can withstand heavy loads and resist wear and tear, making it a durable and long-lasting option.

- ROCPLY Formply F17 AS 6669 certification ensures that it meets Australian standards for formwork plywood, providing peace of mind to builders and contractors.

- The plywood’s resistance to moisture, rot, and termites makes it suitable for use in outdoor construction projects, ensuring that it can withstand harsh weather conditions and remain in good condition.

- ROCPLY Formply F17 smooth surface allows for easy release of formwork, reducing the need for extra release agents and saving time and money.

- The formwork plywood high strength-to-weight ratio makes it easy to handle and transport, reducing the risk of injury and increasing efficiency on the job site.

Formply F17 FAQ

Q: What is ROCPLY F17 Formply?

A: ROCPLY F17 Formply is a high-quality, durable formwork plywood, recognized for its strength and versatility in various construction projects.

Q: What makes ROCPLY F17 formply unique?

A: ROCPLY F17 Formply is unique due to its dual certification under the AS 6669 and AS/NZS 2269 standards, as well as its structural design.

Q: What applications is ROCPLY F17 Formply suitable for?

A: ROCPLY F17 Formply is ideal for various formwork uses, such as constructing decks, precast, and tilt-up panels.

Q: How is ROCPLY F17 Formply manufactured?

A: ROCPLY F17 Formply is manufactured from mixed species veneers bonded together with a super E0 waterproof adhesive, and employs oblique joint and hot-melt splicing technology for superior stability and durability.

Q: What quality control measures are in place for ROCPLY F17?

A: ROCPLY F17 Formply undergoes a rigorous three-tier quality control program, which includes adhering to manufacturing specifications, in-house testing, and external certification by Certemark International (CMI) and the British Standards Institution (BSI).