What are Wood Support Beams?

Wood support beams are structural elements used in construction to bear loads and provide stability to buildings. They are typically made from solid wood or engineered wood products and are essential in framing, supporting roofs, floors, and other building components. Wood beams come in various sizes and types, such as structural wood beam and engineered wood beams, which are designed to meet the specific needs of a construction project. Due to their versatility, wood support beams are used extensively in residential, commercial, and industrial construction to create robust frameworks that ensure the building’s integrity.

Types of Wood Support Beams

Wood support beams come in several types, each suited for different structural applications. Selecting the correct type of beam is crucial for ensuring the stability of the building.

1. Solid Timber Beams

Solid timber beams are a traditional choice for construction projects and are typically made from high-quality softwood or hardwood. They are known for their natural aesthetic and impressive strength, making them ideal for load-bearing applications in residential homes. However, they can be prone to warping and require careful selection to avoid natural defects such as knots or splits.

2. Engineered Wood Beams

Engineered wood beams, such as laminated veneer lumber (LVL) or glulam beams, are crafted by bonding multiple layers of wood veneers or small pieces together. This process results in beams that have consistent quality, enhanced strength, and improved resistance to warping compared to solid wood beams. Engineered wood beams are a popular choice for projects requiring long spans or heavy loads.

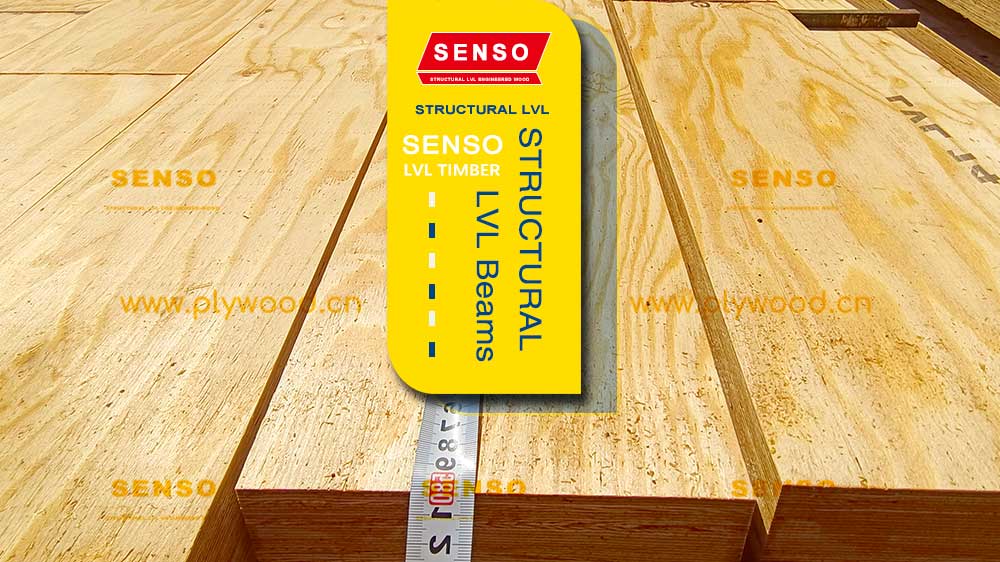

3. LVL Beams

LVL beams are a type of engineered wood beam specifically designed for strength and durability. They are often used in both residential and commercial buildings for supporting heavy loads and creating long spans without the risk of sagging. LVL beams are highly resistant to twisting and shrinking, which makes them an excellent choice for challenging construction conditions.

Choosing the Right Wood Support Beam Size

Selecting the correct wood support beam size is vital for ensuring the structural integrity of a building. Several factors need to be considered when determining the appropriate size, including the span of the beam, the load it will bear, and the type of construction.

Span Considerations

The span of a wood support beam refers to the distance it must cover without additional support. Longer spans require larger beams that can handle increased loads without bending or breaking. Wood beam sizes are determined by consulting load-span tables, which provide detailed information on the allowable span lengths for different beam sizes based on load conditions.

Load-Bearing Requirements

Load-bearing requirements include both dead loads (the weight of the structure itself) and live loads (furniture, occupants, wind, etc.). The beam size must be sufficient to support the combined weight without exceeding its strength limits. It is essential to work with an engineer or builder to determine the appropriate beam size for a given load-bearing application.

Wood Support Beams vs. Steel Beams

One of the common comparisons in construction is between wood support beam and steel beams. Both materials have their advantages, but they serve different purposes based on the project’s requirements.

Strength and Flexibility

Steel beams are incredibly strong and can handle heavy loads over long spans without bending. However, wood support beams are more flexible, easier to work with, and provide natural thermal insulation, which can make them a more suitable choice for residential projects.

Cost and Availability

Wood support beams are generally more affordable and easier to source compared to steel beams. They are also simpler to install, as they do not require specialized equipment for cutting and fastening. This makes them a cost-effective solution for many building projects, especially in residential construction.

Wood Support Beam vs. Engineered Wood Beam

Engineered wood beams, such as LVL and glulam, offer several advantages over traditional solid timber beams, making them a popular choice in modern construction.

Consistent Quality

Engineered wood beams are manufactured under controlled conditions, resulting in consistent quality and strength. Unlike solid timber beams, which may have natural imperfections, engineered beams are uniform in strength, making them a reliable option for load-bearing applications.

Longer Spans

Engineered wood beams can be manufactured in longer lengths than solid timber beams, making them suitable for projects that require long spans without intermediate supports. This is particularly advantageous in open floor plans or large commercial spaces where fewer columns or supports are desired.

Applications of Wood Support Beams in Construction

Wood support beams are versatile and can be used in a variety of construction applications, providing strength and stability where needed.

Residential Homes

In residential construction, wood support beam are used for framing, roof support, and floor joists. Their natural look and ability to provide both aesthetic and structural support make them a popular choice for home builders.

Commercial Buildings

In commercial buildings, engineered wood beams such as LVL and glulam are often used to create large, open spaces without the need for intermediate columns. Their strength and flexibility make them ideal for supporting heavy loads while maintaining an open interior layout.

Roof and Floor Support

Wood support beams are commonly used to support roofs and floors. Their ability to bear significant loads and span long distances without sagging makes them a preferred material for creating stable and durable roof and floor structures.

How to Install Wood Support Beams Safely

Proper installation of wood support beams is essential for ensuring the safety and stability of the structure. The following steps provide a basic overview of how to install wood support beam in a construction project.

Step 1: Planning and Measuring

Before installing a wood support beam, it is crucial to plan and measure the space accurately. This includes determining the span, load requirements, and the exact dimensions of the beam.

Step 2: Preparing the Site

The installation area should be prepared by ensuring that all supports, such as posts or walls, are level and stable. This will help prevent any movement or settling of the beam after installation.

Step 3: Securing the Beam

The beam should be lifted into place and secured using appropriate fasteners or brackets. It is essential to ensure that the beam is level and properly aligned before securing it in place.

FAQs About Wood Support Beams

Q: What are wood support beams used for?

A: Wood support beam are used for framing, roof support, floor joists, and other load-bearing applications in construction.

Q: How do I choose the right wood support beam size?

A: Consider the span and load requirements, and consult load-span tables to determine the correct size for your project.

Q: Are engineered wood beams better than solid timber beams?

A: Engineered wood beams offer consistent quality, longer spans, and better resistance to warping, making them a reliable choice for many projects.

Q: Can wood support beams be used in commercial buildings?

A: Yes, wood support beam, especially engineered types like LVL and glulam, are often used in commercial construction for their strength and versatility.

Q: How should wood support beams be installed?

A: Proper installation includes planning and measuring, preparing the site, and securing the beam with appropriate fasteners or brackets.

Post time: Feb-04-2025