What are Timber Frame Beams?

Timber frame beams are a critical structural element in construction, offering support and strength to buildings. These beams, typically crafted from wood, form the skeleton of a structure, supporting walls, floors, and roofs. Historically, timber frames were the cornerstone of construction, with large, solid beams providing durability. However, with advancements in technology, engineered wood products like LVL (Laminated Veneer Lumber) beams have become increasingly popular. Timber frame beams vary in type, size, and material, influencing the strength and durability of the structure they support.

The use of timber frame beams is common in residential, commercial, and even industrial constructions. Timber framing involves placing beams horizontally and vertically to form the structural framework. Today, beams can be made from natural timber or engineered materials like LVL beams. LVL beams offer enhanced stability and uniformity compared to traditional timber. This comparison explores the pros and cons of timber beams and framing LVL. It helps you decide which option best suits your construction needs.

Timber Frame Beams vs. Framing LVL Beams

The Evolution of Timber Framing

Timber framing has been a mainstay in construction for centuries. Traditional timber beams, often sourced from oak, pine, or fir, are known for their natural beauty and resilience. However, natural timber has its limitations, particularly when it comes to uniformity and susceptibility to environmental factors such as moisture or pests.

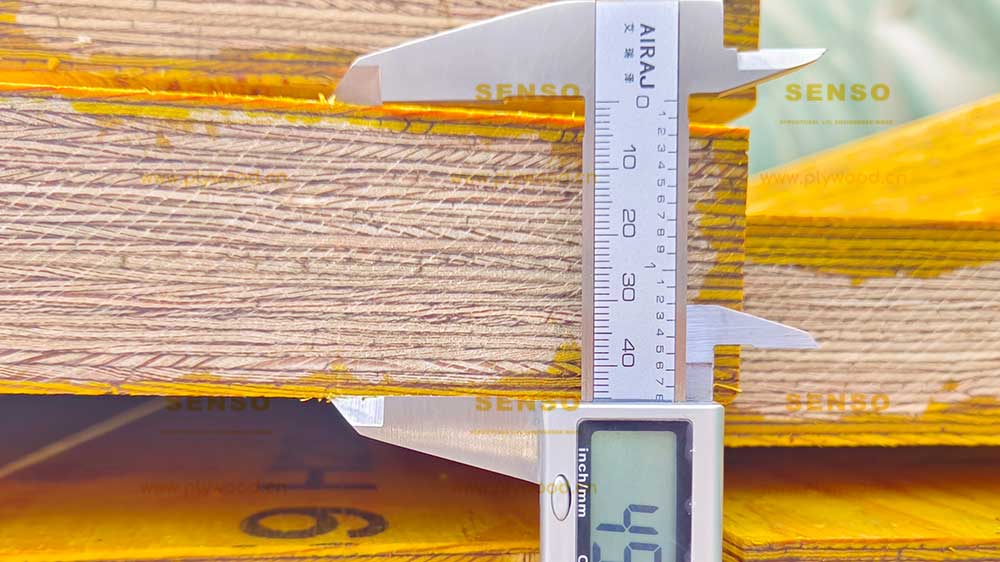

With the introduction of engineered products like LVL beam, timber framing has evolved. Framing LVL beams are created by layering thin sheets of wood veneer and bonding them together with strong adhesives. This process creates a stronger and more durable product. LVL beams are less prone to warping and defects compared to natural timber. Their consistency and strength make them popular in modern construction. LVL beams are a suitable replacement for traditional timber beams.

Strength and Durability

One of the key factors when choosing between timber frame beam and framing LVL beams is strength. Traditional timber beams can vary in strength depending on the quality of the wood and its moisture content. Over time, natural timber can warp or crack, especially when exposed to varying environmental conditions.

LVL beams, on the other hand, are engineered to be stronger and more stable. Since they are made from multiple layers of wood veneer, they are less prone to defects and can bear more weight than a similarly sized timber beam. This makes LVL beams an ideal choice for larger constructions, where uniformity and strength are paramount.

Cost Comparison

The cost of timber frame beams versus framing LVL beams can vary depending on several factors. Natural timber is often more expensive upfront, especially when using high-quality wood like oak or fir. However, engineered LVL beams are often more affordable due to the manufacturing process that utilizes thinner wood veneers, which are cheaper than solid timber. Additionally, LVL beams offer long-term cost savings since they are less likely to require replacement or repairs over time.

When considering cost, it’s essential to think about not only the initial price but also the long-term benefits. LVL beams may offer better value in the long run due to their durability and lower maintenance requirements.

Environmental Considerations

Sustainability of Timber Frame Beams

Sustainability is a critical factor in today’s construction industry. Timber is a renewable resource, and responsible timber sourcing practices can make timber frame beams a sustainable option. When timber is harvested from well-managed forests, it can be a more environmentally friendly choice compared to other building materials like steel or concrete.

However, the environmental impact of timber beams depends on how the wood is sourced and treated. The use of chemical treatments to protect the wood from pests or moisture can reduce its environmental benefits. It is essential to ensure that the timber used in construction is certified by organizations like the Forest Stewardship Council (FSC) to ensure sustainable practices.

LVL Beams and Their Environmental Impact

LVL beams also offer an eco-friendly solution. Since they are made from thin wood veneers, they make efficient use of wood resources. The manufacturing process of LVL beams generates less waste compared to the production of solid timber beams, making them an environmentally conscious choice. Additionally, LVL beams are often manufactured using fast-growing tree species, reducing the strain on slower-growing hardwood forests.

Both timber beams and LVL beams can be environmentally friendly, but the key lies in responsible sourcing and manufacturing practices.

Aesthetics: Timber Beam vs. LVL Beams

Natural Beauty of Timber Frame Beams

One of the primary reasons people choose traditional timber beams is the natural aesthetic appeal of wood. Timber beams add warmth and character to a structure. Each piece of wood has its own unique grain pattern and color. In exposed beam construction, timber framing becomes a focal point. It creates a rustic or traditional look that is hard to replicate with other materials.

The Aesthetic Flexibility of LVL Beams

LVL beams, while not as visually appealing as natural timber beams in their raw form, can be easily adapted to match the desired aesthetic. Since LVL beams are typically covered with finishes or cladding, they can blend seamlessly into modern construction designs. This flexibility allows LVL beams to be used in a wide range of architectural styles, from contemporary to industrial.

While traditional timber beams may offer more inherent beauty, LVL beams provide versatility in terms of design and application.

Installation and Handling of Timber Frame Beams and LVL Beams

Ease of Installation: Timber Frame Beams

Timber frame beams, especially those sourced from solid wood, can be heavy and difficult to maneuver on-site. Handling large, natural timber beams requires specialized equipment and expertise, which can add to the overall labor costs. Furthermore, natural timber can be inconsistent in size and shape, requiring adjustments during installation.

For smaller projects or those with aesthetic exposure, timber frame beams may still be the preferred choice due to their natural look. However, it’s essential to consider the additional labor and time required for proper installation when opting for traditional timber beams.

Advantages of LVL Beams in Installation

In contrast, LVL beams are engineered for uniformity and are lighter than their solid wood counterparts. They are easier to handle on-site and can be cut to precise lengths, making installation faster and more straightforward. The uniformity of LVL beams also reduces the need for adjustments during construction, which can significantly reduce labor costs.

Moreover, LVL beams have the added advantage of being manufactured in longer lengths than most timber frame beams. This allows for fewer joints in the structure, which not only speeds up construction but also improves the overall strength of the building.

Moisture Resistance and Longevity

Timber Frame Beams and Moisture Vulnerability

Natural timber beam, while strong and aesthetically pleasing, are vulnerable to moisture-related issues like rot, mold, and warping. Without proper treatment and maintenance, timber frame beams can degrade over time, particularly in environments with high humidity or rainfall. To mitigate these risks, timber beams must be treated with preservatives, which adds to the cost and environmental impact of using traditional timber.

LVL Beams: Resistant and Long-Lasting

LVL beams are inherently more resistant to moisture than traditional timber beams due to their engineered composition. The manufacturing process of LVL beams involves bonding multiple layers of wood veneer. This provides enhanced stability and resistance to warping. LVL beams can also be treated with moisture-resistant coatings. This makes them a better option for construction in areas prone to humidity or damp conditions.

In terms of longevity, LVL beams typically outperform traditional timber beams, especially when used in harsh environmental conditions. While natural timber beams may require periodic treatment and maintenance to ensure their durability, LVL beams offer a low-maintenance, long-lasting solution.

Flexibility in Design and Use

Versatility of Timber Frame Beams

Timber frame beams have been used in various construction styles, from rustic cabins to modern homes with exposed beam designs. The versatility of timber allows for a wide range of architectural possibilities, and timber beams can be cut and shaped to meet specific design requirements.

One of the main advantages of timber frame beams is their ability to be left exposed, providing both structural support and a visually striking design element. For those looking to create a traditional or rustic aesthetic, timber beams remain a popular choice.

Design Adaptability of LVL Beams

LVL beams, though not typically left exposed, offer tremendous design flexibility. Their strength and uniformity allow for use in larger, more complex structures where natural timber may not be practical. LVL beams can also be used in conjunction with other materials, such as steel or concrete, to create hybrid structures that combine the best of both worlds in terms of aesthetics and strength.

LVL beams can also be incorporated into designs that prioritize modern or minimalist aesthetics, where the beams are hidden within walls or ceilings. Their adaptability to different architectural styles makes them an attractive option for contemporary buildings.

Fire Resistance and Safety Considerations

Timber Frame Beams and Fire Risks

When it comes to fire resistance, traditional timber frame beams are inherently combustible. Larger timber beams can withstand fires longer than smaller wood components. This is due to their size and density. However, they are still at risk of burning. Fire retardants can be applied to timber beams to improve their fire resistance. This, however, adds to the cost and complexity of using natural timber in construction.

LVL Beams and Fire Performance

LVL beams offer better fire resistance compared to standard timber beams due to their engineered composition. In many cases, LVL beams can be manufactured with fire-retardant treatments, making them a safer option in fire-prone areas. Additionally, LVL beams tend to char more slowly than solid wood beams, which can provide critical extra time for evacuation or fire suppression during an emergency.

For projects where fire safety is a top priority, LVL beams often provide a more reliable and safer solution than traditional timber framing.

Weight and Structural Load Capacity

Structural Load Capacity of Timber Frame Beams

The weight and structural load capacity of timber frame beams can vary significantly depending on the type of wood used. Hardwoods such as oak or hickory are denser and provide higher load-bearing capacity than softer woods like pine. However, this added strength comes at the cost of increased weight, making installation more labor-intensive.

In cases where large, solid timber beams are required to support significant structural loads, additional bracing and support may be necessary to ensure safety. This can complicate construction and increase costs.

LVL Beams and Structural Efficiency

LVL beams are engineered for maximum strength and load-bearing capacity, making them more efficient than solid timber beams of the same size. Due to their layered construction, LVL beams distribute weight more evenly and can handle higher loads without the need for additional bracing or support.

The lighter weight of LVL beams also makes them easier to transport and install, reducing labor costs and project timelines. For large-scale construction projects, LVL beams are often the preferred choice due to their structural efficiency and ease of use.

Timber Frame Beams Frequently Asked Questions

Q1: What are the main differences between timber frame beams and LVL beams?

A: Timber frame beams are made from solid wood, offering a natural aesthetic, while LVL beams are engineered from multiple layers of wood veneer, providing greater uniformity and strength.

Q2: Which is more cost-effective: timber frame beams or LVL beams?

A: LVL beams tend to be more cost-effective due to their lower material costs, easier installation, and longer lifespan compared to traditional timber frame beams.

Q3: Are LVL beams better for modern construction?

A: LVL beams are often preferred in modern construction for their strength, uniformity, and ease of installation. They can also be used in larger structures where traditional timber might not be sufficient.

Q4: Can timber frame beams be treated for moisture resistance?

A: Yes, timber frame beams can be treated with preservatives to resist moisture, but this adds to the cost and maintenance requirements.

Q5: Which is more environmentally friendly: timber or LVL beams?

A: Both can be environmentally friendly if sourced and manufactured responsibly. Timber is renewable, while LVL beams make efficient use of wood resources by using thin veneers from fast-growing species.

Q6: Are LVL beams safer in fire-prone areas?

A: Yes, LVL beams often provide better fire resistance than traditional timber beams, especially when treated with fire-retardant materials.

Post time: Oct-14-2024