The World of Formwork LVL

Formwork LVL, commonly known as LVL beams, has carved its niche in the construction realm. As an innovation that combines strength, versatility, and adaptability, it is increasingly becoming the material of choice for modern infrastructure projects. Dive into the intricate world of this engineering marvel and uncover why SENSO is a pioneer in its domain.

The Essence of Formwork LVL

The term “formwork LVL” stands for Laminated Veneer Lumber beams tailored specifically for formwork applications. This engineered wood product is crafted by bonding multiple thin wood veneers under heat and pressure. The resulting structure is not only resilient but also possesses uniform strength, making it a fitting solution for complex construction needs.

SENSO Journey with Formwork LVL

SENSO, with its unwavering commitment to quality and innovation, recognized the potential of formwork LVL early on. Their journey:

Embracing Technology: SENSO leveraged advanced manufacturing techniques to produce LVL beams that exceed industry standards.

Commitment to Sustainability: Harvesting raw materials responsibly, SENSO ensures an eco-friendly approach throughout the LVL production lifecycle.

Customization for Clients: Understanding that every project is unique, SENSO offers tailor-made LVL solutions to meet specific requirements.

Why Formwork LVL Over Traditional Materials?

Consistency & Reliability: Unlike natural timber, which may have inconsistencies, LVL beams promise uniformity. This means builders can trust the material’s strength and stability across its length.

Flexibility in Design: LVL beams can be molded into various shapes and sizes, offering architects greater creative freedom.

Durability: Thanks to its manufacturing process, formwork LVL is resistant to warping, splitting, and shrinking, thus ensuring longevity.

Safety First: Given its predictable strength, using LVL reduces risks associated with construction, making sites safer.

Economic Viability: While upfront costs may be higher than natural timber, the longevity and reduced waste of LVL beams translate to cost savings in the long run.

SENSO Formwork LVL: A Cut Above the Rest

While the market offers multiple LVL options, SENSO stands out due to its uncompromising quality standards and client-centric approach. The brand’s commitment to sustainability, coupled with its focus on innovation, has earned it a sterling reputation in the industry.

Applications of Formwork LVL: Beyond the Basics

In the construction industry, the flexibility and adaptability of a material play a pivotal role in determining its applicability. SENSO formwork LVL stands as a testament to versatility, catering to a wide range of projects.

High-Rise Buildings: The intrinsic strength of LVL beams, paired with their lightweight nature, make them perfect for skyscraper projects where stability is paramount.

Bridges and Overpasses: Their resistance to environmental factors such as moisture and heat ensures longevity in such structures.

Residential Construction: LVL beams bring both aesthetics and strength, meeting the dual demands of modern residential projects.

Temporary Structures: Be it event platforms or temporary shelters; the quick assembly and disassembly benefits of formwork LVL are unparalleled.

Environmental Impact and SENSO Green Approach

As we move towards a sustainable future, the ecological implications of our choices come into focus. Formwork LVL, being an engineered wood product, already has an edge over concrete and steel in terms of carbon footprint. But what about its production?

Responsible Harvesting: SENSO ensures that the wood veneers used are sourced from sustainably managed forests. This practice not only preserves ecosystems but also maintains a balance in nature.

Waste Reduction: The precision in LVL manufacturing means minimal wastage. Any off-cuts or residue from the production process are repurposed, ensuring zero waste.

Energy Efficiency: The production of formwork LVL consumes significantly less energy compared to steel or concrete, further reducing its environmental impact.

The Future of Formwork LVL and SENSO Vision

As urban landscapes evolve, the demand for materials that are efficient, durable, and sustainable intensifies. Formwork LVL beams are poised to play an even more significant role in the construction industry’s future.

Research & Development: SENSO is heavily invested in R&D to push the boundaries of what formwork LVL can achieve. With ongoing research, the possibilities seem endless.

Training & Workshops: To propagate the benefits and correct usage of LVL beams, SENSO organizes training sessions for architects, builders, and students. Knowledge sharing is crucial in driving innovation.

Global Expansion: With a vision to make formwork LVL accessible globally, SENSO is expanding its operations, collaborating with international partners, and setting up distribution channels in untapped markets.

Testimonials from the Frontline: SENSO Formwork LVL in Action

Construction industry leaders and architects worldwide have sung praises for the adaptability and performance of formwork LVL. Here, we delve into some real-world endorsements that validate the prowess of SENSO LVL beams.

A Bridge Over Calm Waters

“Our challenge was to create a pedestrian bridge that could withstand both pedestrian traffic and the unpredictable nature of the Midwest weather. Using SENSO formwork LVL beams, we achieved a structure that’s both elegant and robust. The beams delivered outstanding load-bearing capabilities and a resilience that exceeded our expectations,” says Michael O’Reilly, a prominent civil engineer from Chicago.

Urban Housing Revolutionized

Diane Torres, an architect from New York City, shares her experience: “In the heart of Brooklyn, we were tasked with developing a multi-story residential complex that combined aesthetics with durability. With space constraints and the need for speed in construction, SENSO formwork LVL was our go-to. The result? A modern urban dwelling that resonates with style and strength.”

A Greenhouse Like No Other

SENSO LVL beams have even found their way into more unique projects. Horticulturist Liam Nguyen from San Francisco recounts, “For our community greenhouse project, we wanted a structure that harmonized with nature, and SENSO formwork LVL wooden beam provided just that. Their eco-friendly nature coupled with their robustness made our greenhouse both sustainable and enduring.”

Care & Maintenance: Ensuring Longevity of Formwork LVL

Every construction material requires some degree of care to maintain its pristine condition and ensure a prolonged lifespan. SENSO LVL wood beam beams, while durable, are no different.

Regular Inspections: Periodically check for any signs of wear or damage. While SENSO glulam beam are built to last, catching minor issues early can prevent significant problems down the line.

Protection from Excess Moisture: Although treated for moisture resistance, it’s advisable to keep the beams dry whenever possible, especially in prolonged wet conditions.

Safe Storage: If storing LVL beams for future use, ensure they’re kept in a dry, shaded place, preferably off the ground.

Custom Solutions with SENSO

Every construction project is unique, with specific demands and challenges. Recognizing this, SENSO offers customized solutions tailored to individual project needs.

Whether it’s a particular size, finish, or treatment, SENSO commitment to innovation ensures that clients get formwork LVL beams precisely as per their requirements.

Benefits of Banking on SENSO for Formwork LVL

The construction industry is perpetually evolving, with materials and techniques transforming to meet the demanding requirements of modern architectural marvels. Amidst this evolution, SENSO formwork LVL beams stand out for a plethora of reasons.

Durability Par Excellence: SENSO formwork LVL beams undergo rigorous testing, ensuring they can withstand extreme conditions, from heavy loads to adverse weather. These beams not only promise longevity but also offer consistent performance throughout their life.

Environmentally Conscious: SENSO commitment to a greener planet is evident in its products. By using sustainable sources and methods, SENSO ensures that its formwork LVL beams tread lightly on the Earth, making it an eco-friendly choice for the environmentally aware builder.

Cost-Effective Solutions: High-quality doesn’t always mean high cost. SENSO glulam beam are a testament to this, providing premium quality without breaking the bank. The durability of the beams also means fewer replacements, leading to long-term savings.

Versatility in Application: From residential homes to commercial spaces and even specialty projects like greenhouses, the adaptability of SENSO LVL beams is unparalleled. Their versatility ensures they’re fit for almost any construction challenge thrown their way.

Peering into the Future of Formwork LVL

The trajectory for formwork LVL beams, particularly those from SENSO, is on an upward spiral. As urbanization continues at an unprecedented rate and space becomes a premium, the need for materials that offer strength in slimmer profiles will rise.

SENSO is already at the forefront of this revolution, with ongoing research and development to make their LVL wooden beam even more efficient, sustainable, and adaptable to the ever-changing construction landscape.

Additionally, with global emphasis on sustainability and eco-friendly construction solutions, SENSO environmentally conscious approach places it in an advantageous position to lead the industry into a greener future.

In the vast world of construction, while many materials come and go, some stand the test of time due to their inherent qualities and the vision of the brands behind them. SENSO formwork LVL beams are poised to be one such material, bridging the past’s robustness with the future’s innovations.

Craftsmanship in SENSO Formwork LVL Production

The success behind SENSO formwork LVL doesn’t just lie in the product itself, but in the meticulous craftsmanship that goes into its production. Let’s delve deeper into what makes SENSO manufacturing process truly unique.

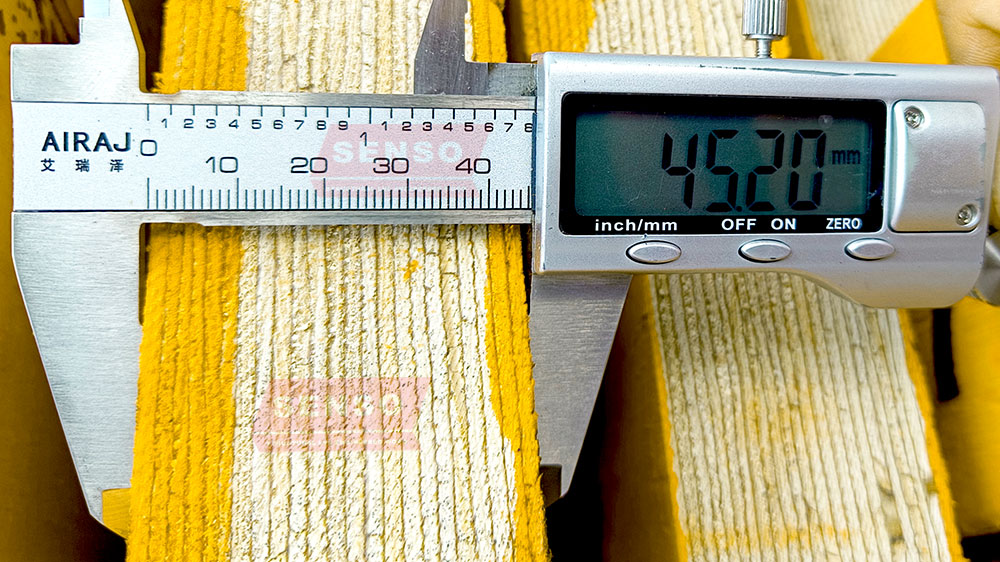

- Precision Engineering: At the heart of SENSO operations is precision. The beams are crafted using state-of-the-art machinery, ensuring uniformity and perfection in every piece. The meticulous attention to detail means that SENSO wood beam fit seamlessly into any project.

- Quality Raw Materials: SENSO understands that the foundation of a superior product is superior raw materials. Only the finest wood sources are chosen, undergoing thorough inspection to ensure they meet the brand’s high standards.

- Sustainable Practices: Beyond just sourcing sustainably, SENSO embeds eco-friendliness in its production processes. The brand continually seeks ways to minimize waste, reduce carbon footprint, and employ energy-efficient methods, championing a greener approach in the industry.

- Expert Workforce: Behind every SENSO glulam beam is a team of skilled professionals with years of experience. Their expertise ensures that every beam not only meets but often surpasses industry standards.

The Global Impression of SENSO Formwork Beams

The formwork LVL market is expansive, with numerous players vying for a spot at the top. Yet, SENSO reputation resonates globally. Why is that?

Pioneering Innovations: SENSO isn’t content resting on its laurels. The brand continually pushes the envelope, introducing innovative solutions that cater to modern construction challenges. Their forward-thinking approach sets them apart in a competitive landscape.

Customer-Centric Approach: SENSO relationship with its clientele goes beyond mere transactions. The brand is committed to understanding and catering to each customer’s unique needs, leading to tailored solutions and impeccable after-sales support.

Consistency is Key: While the construction landscape may shift, SENSO commitment to quality remains unyielding. This consistency in delivering top-notch formwork LVL beams has fostered trust among builders and architects worldwide.

The SENSO Legacy and the Road Ahead

While SENSO has etched a significant mark in the formwork LVL sector, the brand’s vision stretches far beyond. With plans to expand its product lineup, delve deeper into sustainable innovations, and broaden its global footprint, the future looks bright for this industry stalwart.

SENSO dedication to excellence, combined with its future-ready approach, cements its position as not just a brand, but a force to be reckoned with in the world of construction.

Post time: Nov-24-2023